In the quest for a sustainable future, the sun has always been a reliable ally, casting its golden rays to fuel the dreams of a greener tomorrow. As humanity races to harness this boundless energy, solar panels stand at the forefront, capturing sunlight and converting it into the lifeblood of our modern world. But behind the sleek surfaces of these panels lies a technological revolution that is quietly reshaping their creation—3D printing. Once confined to the realms of prototypes and models, 3D printing has emerged as a transformative force in solar panel manufacturing, offering unprecedented possibilities for innovation and efficiency. This article delves into the intriguing intersection of these two cutting-edge technologies, exploring how 3D printing is not only streamlining production but also paving the way for more sustainable and versatile solar solutions. Join us as we illuminate the role of 3D printing in the solar panel industry, where creativity meets practicality in the quest for renewable energy excellence.

Harnessing Precision How 3D Printing Revolutionizes Solar Panel Design

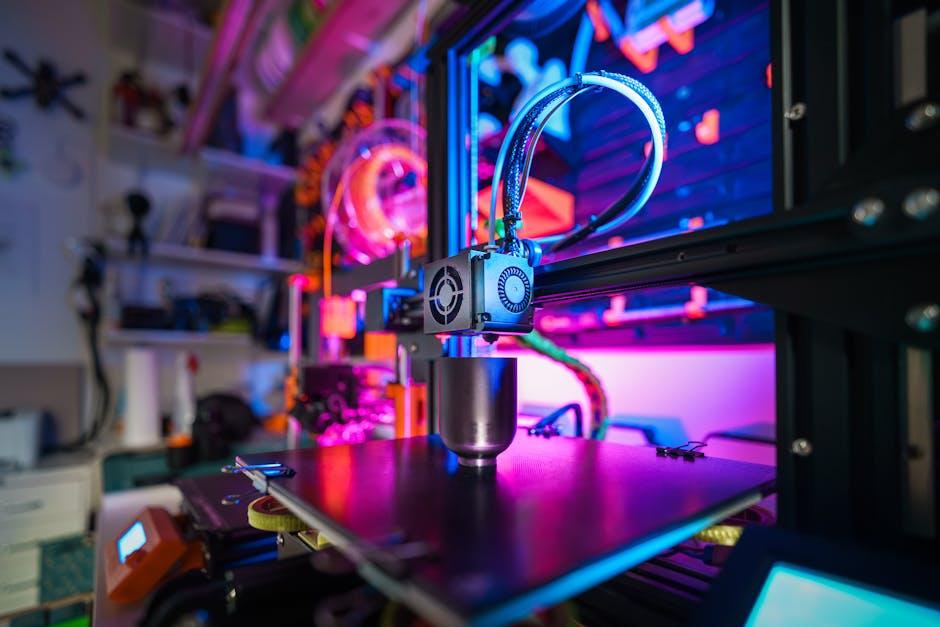

The integration of 3D printing into solar panel manufacturing is a game-changer, offering unparalleled precision and customization capabilities. This innovative approach allows for the creation of complex geometries and intricate designs that were previously impossible with traditional manufacturing techniques. 3D printing enables the production of lighter and more efficient solar cells by optimizing material usage and reducing waste, which is crucial for both economic and environmental sustainability.

- Enhanced Design Flexibility: Engineers can experiment with unique shapes and sizes to maximize sunlight capture.

- Material Innovation: New materials can be tested and implemented quickly, improving the efficiency of solar cells.

- Cost Reduction: By minimizing waste and lowering production costs, solar panels become more accessible.

Moreover, 3D printing facilitates rapid prototyping, enabling faster iterations and innovations in solar technology. This agility in design and production not only accelerates development but also encourages sustainable practices by allowing for local manufacturing, thus reducing the carbon footprint associated with transportation. As the demand for renewable energy grows, the will undoubtedly expand, leading to more sustainable and efficient energy solutions.

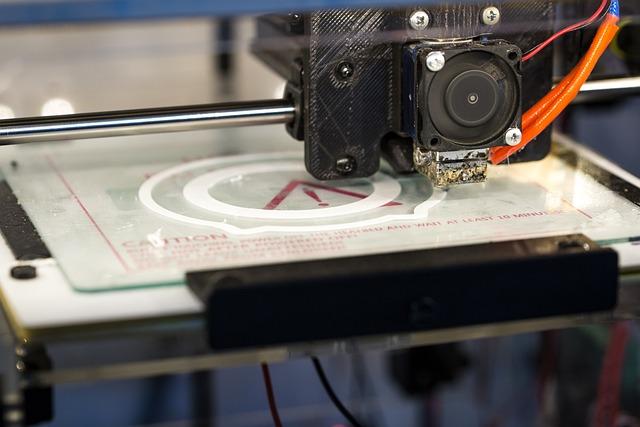

From Prototype to Production Exploring Efficiency Gains in Solar Manufacturing

The integration of 3D printing into solar panel manufacturing is reshaping the landscape of renewable energy production. This cutting-edge technology facilitates the creation of intricate solar cell designs that were previously unattainable with traditional manufacturing methods. By leveraging the precision of 3D printing, manufacturers can reduce material waste, optimize component performance, and accelerate the prototyping phase. This not only decreases production costs but also enhances the overall efficiency of solar panels.

- Customized Designs: Tailor solar cells to specific energy needs and environmental conditions.

- Rapid Prototyping: Swiftly iterate designs to perfect energy output and durability.

- Material Efficiency: Minimize waste through precise material deposition and utilization.

- Scalability: Easily transition from small-scale prototypes to mass production.

These advancements mark a significant step forward, enabling manufacturers to meet the growing demand for clean energy solutions while maintaining competitive pricing. As the solar industry continues to evolve, the role of 3D printing is poised to become increasingly pivotal, driving innovation and sustainability in solar panel production.

Innovative Materials The Role of 3D Printing in Advancing Solar Technology

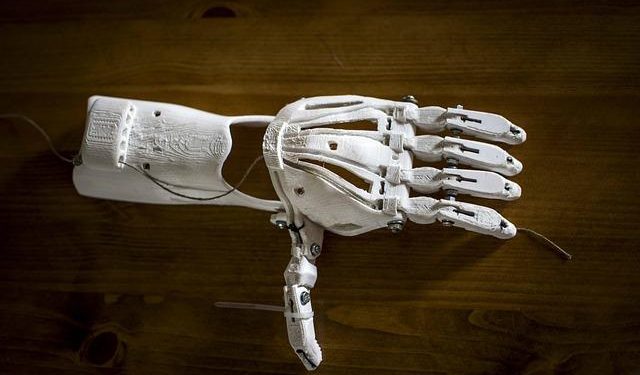

In the quest to enhance solar technology, 3D printing emerges as a transformative force, redefining the landscape of solar panel manufacturing. By leveraging the precision and adaptability of 3D printing, manufacturers can now experiment with innovative materials that were previously challenging to integrate into traditional production processes. These materials include:

- Perovskite solar cells: Offering a promising alternative to silicon-based cells, perovskite materials are easier to produce and potentially more efficient. 3D printing allows for precise layering and structuring, enhancing their performance and longevity.

- Conductive polymers: These lightweight and flexible materials can be seamlessly incorporated into solar panels, thanks to the detailed customization capabilities of 3D printing, opening doors to new applications and design possibilities.

- Transparent conductive films: Essential for the development of bifacial and semi-transparent solar panels, these films benefit from 3D printing’s ability to create complex geometries and fine features.

With these advancements, 3D printing not only reduces material waste and production costs but also accelerates the development of next-generation solar technologies. This integration of innovative materials and advanced manufacturing techniques propels the industry toward a more sustainable and efficient future.

Strategic Implementation Best Practices for Integrating 3D Printing in Solar Panel Production

When embarking on the integration of 3D printing technology in solar panel production, companies must focus on several best practices to ensure strategic success. Collaboration across departments is crucial; R&D teams should work closely with manufacturing and supply chain units to align goals and identify the most impactful 3D printing applications. Additionally, it is essential to conduct a comprehensive analysis of the current production processes to pinpoint where 3D printing can add value, such as in the customization of panel components or the rapid prototyping of innovative designs.

Another critical factor is investing in training and development. Ensuring that the workforce is well-versed in both the technical and practical aspects of 3D printing will facilitate smoother implementation. Companies should also consider building partnerships with 3D printing experts and technology providers to stay abreast of the latest advancements. To foster a culture of innovation, organizations can establish a pilot program to test 3D printing applications on a smaller scale before a full-scale rollout. These steps not only enhance the integration process but also position the company as a leader in cutting-edge solar panel manufacturing.

- Foster interdepartmental collaboration to align objectives.

- Analyze existing processes for 3D printing opportunities.

- Invest in workforce training to build expertise.

- Build strategic partnerships with technology providers.

- Establish pilot programs to test applications.

Wrapping Up

As we stand on the cusp of a renewable energy revolution, the intersection of 3D printing and solar panel manufacturing emerges as a beacon of innovation. This synergy not only promises enhanced efficiency and reduced costs but also heralds a future where sustainability is within reach. The layers of potential are as limitless as the sun’s rays, casting a bright light on the possibilities that lie ahead. As we continue to explore and refine these technologies, the horizon of solar energy becomes not just a distant dream, but an achievable reality. In this dynamic dance of technology and sustainability, 3D printing steps in as a pivotal partner, reshaping the way we harness the sun’s power and illuminating the path to a greener tomorrow.